Reimagining Business Growth through Industry 4.0: An In-depth Look at Smart Factories

The concept of smart factories has its roots in Germany's Industry 4.0 initiative, launched back in 2011. This strategic move aimed at transforming the industrial sector through the integration of digital technology and automation. Over the years, this idea has evolved into a global phenomenon, with companies of various sectors striving to upgrade their manufacturing processes into smart operations.

The Present Scenario: Smart Factories Reshaping Business Landscape

In the current business environment, smart factories are no longer a distant dream but a practical reality. Leveraging cutting-edge technologies like machine learning, big data, and advanced robotics, these highly digitized and connected production facilities have been able to dramatically enhance efficiency and productivity. Companies that adopt smart factory practices are experiencing operational improvements, cost reductions, and enhanced product quality.

The Impact of Smart Factories on Business and Industry

The advent of smart factories has brought a paradigm shift in business and industrial operations. On one hand, it promises a plethora of benefits such as improved efficiency, reduced waste, and increased flexibility. On the other hand, it poses challenges such as the need for skilled labor, cybersecurity risks, and substantial investment requirements.

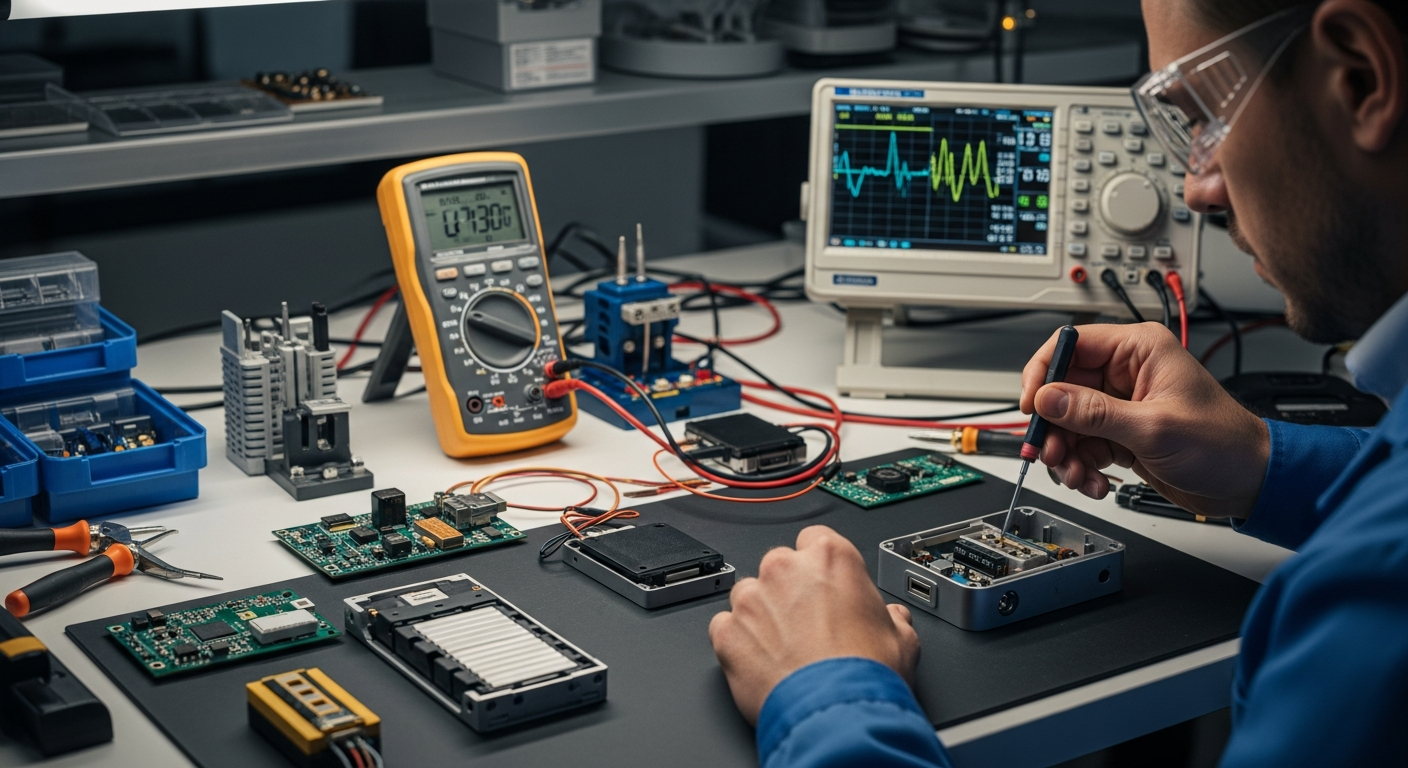

The Power of Data in Smart Factories

One of the most striking features of smart factories is their ability to generate and harness vast amounts of data. From real-time monitoring of machinery to predictive maintenance, data is driving unprecedented levels of efficiency and productivity. However, businesses need to have robust data management strategies in place to leverage this data effectively.

Future Trends: The Next Wave of Smart Factory Innovation

As we move forward, the evolution of smart factories is set to accelerate, driven by advancements in technologies such as artificial intelligence, IoT, and 3D printing. Businesses that can proactively adapt to these trends and invest in the necessary infrastructure and skills are likely to emerge as industry leaders.

Pivotal Points for Success in Smart Factories

-

Embrace change: Business leaders should foster a culture of innovation and encourage employees to embrace new technologies and processes.

-

Invest in workforce development: The success of smart factories hinges on a skilled workforce. Companies must invest in training and development to equip their employees with the necessary skills.

-

Prioritize cybersecurity: With increased connectivity comes increased vulnerability to cyber threats. Businesses must prioritize cybersecurity to protect their operations and data.

In conclusion, smart factories represent the convergence of the physical and digital worlds, offering a new paradigm for business growth and industrial progress. While the journey towards fully digitized, connected, and intelligent manufacturing facilities is fraught with challenges, the potential rewards in terms of efficiency, productivity, and competitiveness are immense. Businesses that can effectively navigate this transition and leverage the power of data and automation stand to gain a significant competitive edge.