Enhancing Operational Efficiency in Industrial Sectors

Operational efficiency is a critical driver for success across industrial sectors, encompassing everything from manufacturing to complex supply chains. It involves streamlining processes, optimizing resource utilization, and adopting innovative approaches to achieve higher output with reduced waste and cost. For businesses operating in a competitive global market, a strong focus on efficiency can lead to significant advantages, fostering sustainable growth and resilience against economic fluctuations.

Understanding Operational Efficiency in Industrial Contexts

Operational efficiency in industrial settings refers to the ability of an organization to produce goods or services in the most effective and economical manner possible. This involves evaluating and improving every stage of the production process, from raw material procurement to final product delivery. The core objective is to maximize output while minimizing inputs such as time, labor, and capital. For manufacturing operations, this could mean reducing cycle times, improving machine uptime, or decreasing defect rates. A truly efficient enterprise understands that continuous improvement in operations is not a one-time project but an ongoing strategy vital for long-term growth and competitiveness within the industry.

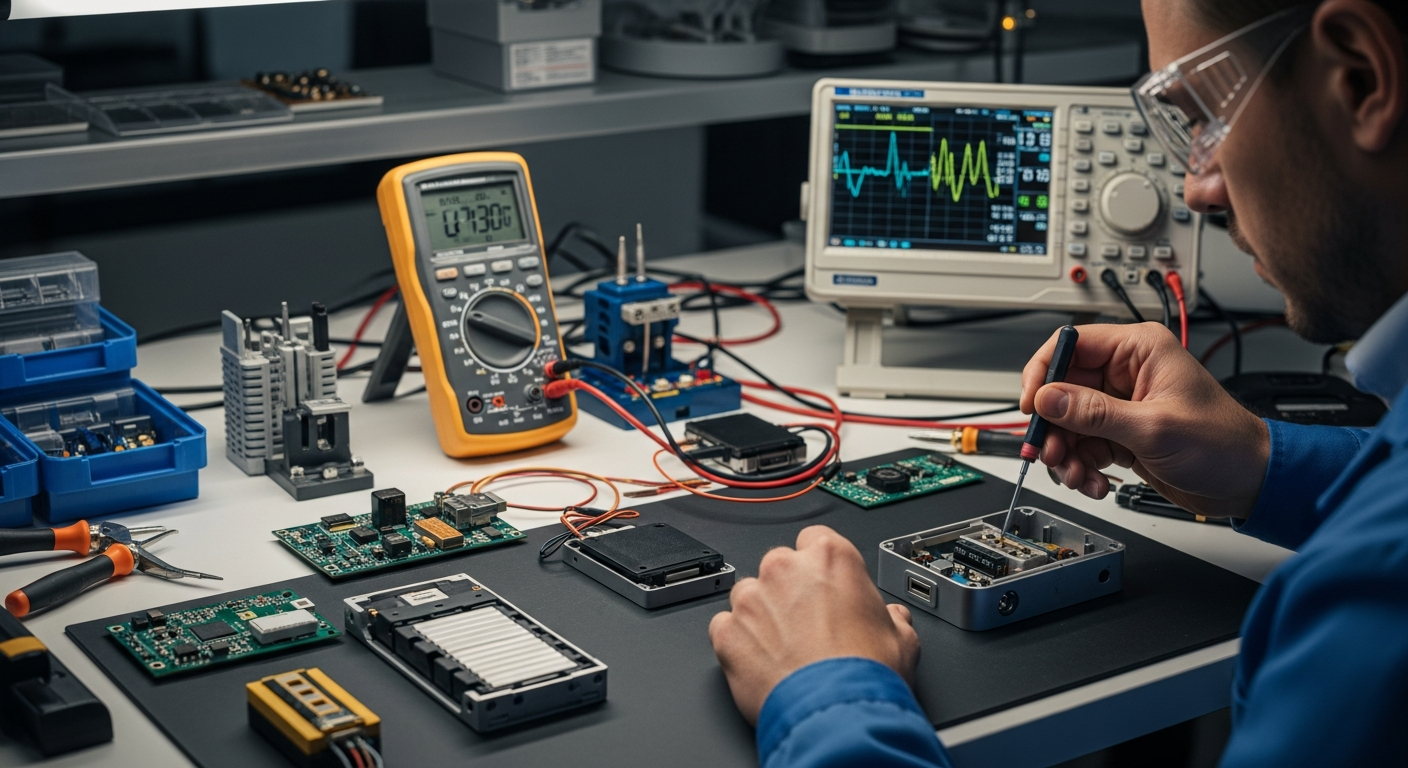

The Role of Technology and Automation in Modern Production

Modern industrial efficiency is increasingly powered by technology and automation. The integration of advanced machinery, robotics, and artificial intelligence into production lines allows for greater precision, speed, and consistency than manual processes. Digital tools, such as IoT sensors and data analytics platforms, provide real-time insights into operations, enabling proactive problem-solving and predictive maintenance. This level of innovation is transforming manufacturing, making it possible to achieve higher output with fewer errors and less downtime. Embracing digital transformation is no longer optional but a fundamental requirement for companies aiming to remain relevant in the evolving market and contribute positively to the broader economy.

Optimizing Supply Chain and Logistics for Global Commerce

Effective supply chain management and logistics are indispensable for enhancing operational efficiency, particularly in global commerce. A well-optimized supply chain ensures that materials and products move seamlessly from suppliers to customers, reducing lead times and transportation costs. This involves careful planning, coordination, and the strategic use of data to predict demand, manage inventory, and mitigate risks. For businesses operating across international borders, understanding global trade regulations and having robust logistics networks are paramount. Streamlining these processes directly impacts a company’s ability to deliver value, respond to market changes, and maintain a competitive edge, fostering overall development within the industry.

Developing Strategies for Sustainable Enterprise Growth

Sustainable enterprise growth is intrinsically linked to a well-defined strategy for operational efficiency. This involves not only implementing new technology and automation but also fostering a culture of continuous improvement across all levels of the organization. Strategic planning should encompass regular performance reviews, employee training programs focused on new digital tools, and an agile approach to adapting to market demands. Companies that prioritize innovation in their operations often find themselves better positioned to weather economic shifts and capitalize on new opportunities. By consistently seeking ways to optimize production and commerce, businesses can ensure long-term viability and contribute significantly to the economy and its development.

In conclusion, enhancing operational efficiency within industrial sectors is a multifaceted endeavor that requires a holistic approach. It integrates technological advancements, strategic management of the supply chain, and a commitment to continuous improvement. By focusing on these key areas, industrial enterprises can not only improve their production capabilities and reduce costs but also strengthen their position in the global market, ensuring sustainable growth and resilience for the future.